The Complete Guide to Self-Adhesive Sticker Materials: Composition, Applications, and Technical Considerations

Self-adhesive sticker materials—commonly known as pressure-sensitive label stocks—represent one of the most versatile and technically sophisticated components in modern packaging, branding, and industrial identification. Unlike traditional labels that require water, heat, or separate adhesives for application, self-adhesive materials feature a pre-coated adhesive layer that bonds to surfaces under light pressure. This simple mechanism hides a remarkably complex interplay of material science, chemistry, and manufacturing engineering.

Structure of Self-Adhesive Sticker Materials

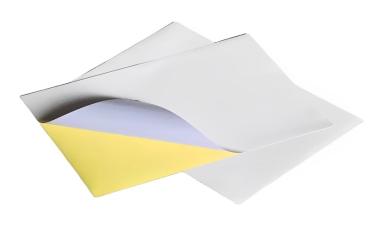

A self-adhesive sticker is not just a single sheet; it’s a multilayered laminate engineered for performance, printability, and durability.

The typical structure includes:

- Face Stock (Top Layer): The printable surface or substrate that carries the image, text, or barcode.

- Materials: Paper (coated/uncoated), polypropylene (PP), polyethylene (PE), polyester (PET), vinyl (PVC), or specialty films (e.g., holographic, metallic, or heat-resistant).

- Thickness: Generally ranges from 50–200 microns.

- Properties: Must exhibit dimensional stability, ink adhesion compatibility, and mechanical durability.

- Adhesive Layer: The bonding agent that adheres the sticker to the substrate surface.

- Types: Permanent, removable, repositionable, ultra-removable, high-tack, low-tack, or specialty adhesives (e.g., for extreme temperatures or chemical exposure).

Chemistries:

- Acrylic-based: Offers UV stability, clarity, and weather resistance.

- Rubber-based: Provides higher initial tack and stronger adhesion to rough or low-energy surfaces.

- Silicone-based: Used for extreme temperature ranges or low-surface-energy substrates (e.g., Teflon, silicone rubber).

Release Liner (Backing Paper or Film):

Protects the adhesive until the sticker is applied.

- Materials: Glassine paper, clay-coated kraft (CCK), polyethylene-coated paper, or PET film.

- Coating: Silicone release coating ensures easy peel-off without damaging the adhesive layer.

This three-layer construction is often laminated with precise tension control and curing processes to achieve consistent adhesion, smooth die-cutting, and stable performance across printing and application environments.

Types of Self-Adhesive Sticker Materials

Paper-Based Stickers

Paper labels remain cost-effective and widely used for general product labeling, office supplies, and packaging.

- Coated Paper: Smooth surface, suitable for offset, flexographic, and digital printing.

- Uncoated Paper: Economical and writable, commonly used for logistics labels.

- Thermal Paper: Reacts to heat from thermal printers—ideal for barcode and point-of-sale systems.

Advantages: Easy to print, biodegradable options available.

Limitations: Poor resistance to moisture, UV exposure, and chemicals.

Film-Based Stickers

Used for high-performance, durable, or visually striking applications.

Polypropylene (PP):

- Good stiffness and transparency.

- Resistant to water, oil, and chemicals.

- Common for cosmetic, beverage, and health product labels.

Polyethylene (PE):

- Flexible and conformable, suitable for curved surfaces.

- Resistant to tearing, moisture, and impact.

Polyester (PET):

- Excellent dimensional stability and temperature resistance.

- Used for electronics, automotive parts, and industrial ID tags.

Vinyl (PVC):

- Highly durable and weather-resistant.

- Preferred for outdoor graphics, signage, and long-life labels.

Note: Environmental regulations are reducing PVC usage due to chlorine-based manufacturing concerns.

Specialty and Functional Stickers

These advanced materials are engineered for specific environments or purposes:

- Tamper-Evident Films: Fracture or leave residue when removed, used for security seals.

- Void Labels: Reveal hidden text (“VOID”) upon tampering.

- Heat-Resistant Labels: Withstand up to 300°C for electronics manufacturing.

- Cryogenic Labels: Maintain adhesion at -196°C for laboratory vials.

- Eco-Friendly Films: Made from biodegradable PLA or recycled polymers.

Technical Considerations in Production and Application

Surface Energy and Adhesion

Adhesive performance depends on surface energy—high-energy surfaces (e.g., metals, glass) promote stronger bonding than low-energy plastics (e.g., polyethylene). Manufacturers often pre-treat low-energy surfaces with corona, flame, or plasma treatments to enhance wettability.

Application Environment

Temperature, humidity, and surface cleanliness critically affect adhesion.

- Application Temperature Range: Typically 5°C–50°C.

- Service Temperature Range: -40°C to +150°C depending on adhesive chemistry.

Printing Technologies

Self-adhesive materials support diverse printing methods:

- Flexographic Printing: Most common for mass production.

- Digital Printing (Inkjet, Laser, or Thermal Transfer): Enables short runs and variable data.

- Screen Printing: Suitable for opaque, UV-resistant designs.

- Gravure Printing: High-resolution, premium packaging.

Pre-treatment coatings or corona discharge are often applied to ensure ink anchorage.

Die-Cutting and Finishing

Precision die-cutting (rotary or flatbed) ensures clean label edges without adhesive ooze. Matrix stripping, slitting, and rewinding are critical for roll-to-roll consistency.

Storage and Handling

- Store at 20–25°C with 50–60% relative humidity.

- Avoid prolonged exposure to UV light or heat before application.

Quality and Testing Standards

To ensure performance and compliance, self-adhesive sticker materials are tested under multiple international standards, such as:

- FINAT (Europe): Defines peel adhesion, shear, and tack testing protocols.

- ASTM (U.S.): Methods for adhesive bond strength and aging resistance.

- ISO 22382: Standards for security printing and tamper-evident materials.

Key performance tests include:

- Peel Strength (FINAT Test FTM1)

- Shear Adesion (FTM8)

- Tack Measurement (FTM9)

- UV and Chemical Resistance

- Dimensional Stability under Heat

Applications Across Industries

- Consumer Goods: Branding labels, product identification, and promotional graphics.

- Logistics: Barcode and tracking labels for inventory and shipping.

- Automotive: Under-hood and warning labels requiring temperature and solvent resistance.

- Electronics: PCB and asset tracking labels resistant to heat and cleaning solvents.

- Pharmaceuticals: Tamper-evident and cryogenic labels for compliance and traceability.

- Retail: Price tags, shelf-edge labels, and security seals.

- Industrial: Chemical drum labels complying with GHS (Globally Harmonized System).

Sustainability and Future Trends

As environmental regulations tighten, the industry is rapidly evolving:

- Recyclable Label Stocks: Designed for compatibility with PET recycling streams.

- Linerless Labels: Eliminate release liners to reduce waste and improve efficiency.

- Bio-based Adhesives: Derived from renewable sources.

- Water-Soluble and Wash-Off Adhesives: Enable clean recycling of glass and plastic containers.

- Smart Labels: Incorporate RFID, NFC, and temperature sensors for logistics tracking and authentication.

These innovations signal a move toward circular-economy labeling solutions.

Self-adhesive sticker materials embody the convergence of polymer chemistry, materials engineering, and printing science. From simple paper labels to high-performance industrial films, their design and manufacturing require precise control of surface chemistry, adhesive formulation, and lamination processes. As sustainability and digitalization reshape packaging, the future of self-adhesive materials will focus on smarter, greener, and more efficient labeling technologies.